Water Jet Cutting

AR Iron Waterjet Is Better Than Plasma Design

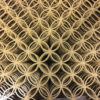

Whether a decorative piece or a machine part, waterjet cutting can turn raw materials into beautiful, accurate reproductions of nearly any CAD design. With waterjet, materials can be cut within a tolerance of +/- 0.005” and with a kerf width of about 0.035”.

Let us help make your imagined product a beautiful reality. Waterjet machining produces finished edges without the pierce spatter, slag, burns, burrs, chips and warping of other cutting processes like laser and plasma. The fine-tuned capabilities of waterjet cutting can even mean sandblasted-type surface effects for materials like granite, stainless steel and neoprene rubber. Practically any effect you could want can be accomplished.

Like many other Las Vegas metalworking shops, we used to rely solely on Plasma Design cutting. While this technology could deliver quick results, it was limited to certain materials like steel and delivered imprecise cuts. Now, with waterjet, we can deliver a much wider range of services with more precision and efficiency than ever before.

AR Iron Are Your Las Vegas and Henderson, NV Waterjet Experts

For nearly 30 years, AR Iron has been Henderson, Nevada’s leading ironworks and wrought iron artisans. We have constantly expanded our services and adopted the latest technologies to deliver a high-quality metalworking experience for our clients.

With waterjet cutting, our precision cutting services can now include a wider variety of materials in thicknesses up to 5” and possibly more. We can work with:

- Stainless steel

- Titanium

- Aluminum

- Granite

- Alloys

- Acrylics

- Laminates

- Wood

- Glass

- Marble

- Brass

- Copper

- Composites

- Tile

Practically any sheet material you can think of!